Exploring Key Types of Gears and Their Industrial Applications

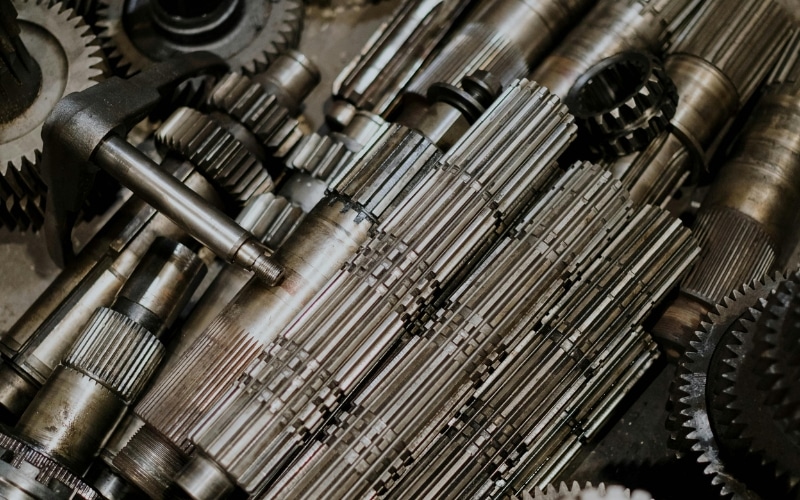

Gears are the hidden heroes behind many machines we rely on daily, from cars to industrial robots. Understanding the different types of gears and their unique characteristics is essential for anyone curious about how things work or involved in designing and maintaining machinery.

Gears are essential components across industries, each serving specific purposes to meet diverse operational needs.

Here’s a breakdown of common gear types and their applications.

Types of Gears

Each type of gear serves specific functions, whether transmitting power efficiently in automotive engines, ensuring precise movements in medical devices, or handling heavy loads in mining equipment. Exploring these gears unveils their engineering intricacies and highlights their crucial roles across diverse industries, shaping the way modern technology operates and evolves.

Spur Gears: These are found in automotive transmissions for direct power transfer.

Helical Gears: Ensure smooth and quiet operation, commonly used in automotive and industrial machinery.

Bevel Gears: Transmit power between intersecting shafts, which is crucial in aerospace for engine systems.

Worm Gears: Provide high torque and precise positioning, used in aerospace landing gear systems.

Rack and Pinion: Convert rotational motion to linear motion, which is essential in industrial CNC machines.

Planetary Gears: Compact and high-torque, ideal for robotics and precision machinery.

Herringbone Gears: Handle high torque and vibrations, commonly used in marine propulsion systems.

Spiral Bevel Gears: Ensure smooth power transmission at varying angles, which is vital in marine engines.

Double Helical Gears: Minimize axial thrust, which is crucial for heavy-duty mining equipment.

Internal Gears: Compact and precise, used in medical imaging devices and surgical robots.

Epicyclic Gears: Provide precise speed control, which is essential in power generation equipment.

Industrial Applications

Understanding how various gear types are used across industries highlights their crucial role in improving efficiency and precision. From automotive transmissions to aerospace systems and beyond, every kind of gear is designed to meet specific operational needs, ensuring smooth performance across different industrial applications.

Automotive Industry: Spur and helical gears in transmissions for efficient power transfer.

Aerospace and Defense: Bevel and worm gears for precise engine and landing gear systems.

Industrial Machinery: Rack and pinion systems in CNC machines for linear motion control.

Marine Industry: Herringbone and spiral bevel gears in propulsion systems for smooth operation.

Energy Sector: Gearboxes with epicyclic gears for precise speed control in turbines and generators.

Mining and Construction: Double helical gears for heavy-duty mining equipment handling.

Medical Equipment: Internal gears in imaging devices and surgical robots for precision.

Oil and Gas Industry: Spur gears with hardened teeth and straight bevel gears for reliable operation in harsh environments.

Food and Beverage Industry: Stainless steel and plastic gears for hygienic food processing and packaging.

Understanding these diverse gear types is crucial for selecting the right components to optimize efficiency and reliability in specific industrial applications. Whether enhancing automotive performance or refining medical equipment, choosing the correct gear type ensures smooth operations tailored to industry-specific needs.

For expert guidance on selecting and maintaining gears for your industry, consult with experienced professionals at MayDay to ensure optimal performance and longevity of your machinery.