Exploring Gearbox Types: A Guide for Industrial Machinery, Automotive, and More

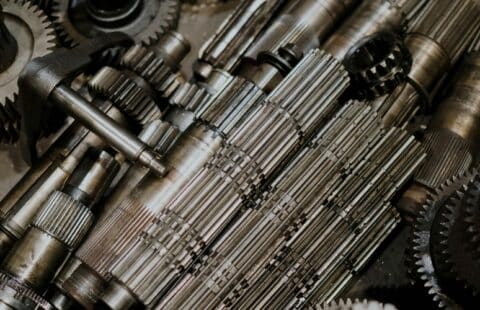

Welcome to the powerhouse of industrial machinery—the gearbox. Whether you’re navigating the precision of medical equipment or commanding the might of construction vehicles, understanding gearbox types is like mastering the gears of progress themselves. At the heart of these mechanical marvels lies a world of spinning, meshing, and transmitting power.

Let’s uncover the essential types that drive industries forward, ensuring machines operate smoothly and efficiently.

Gearbox Types

Spur Gears: These are the workhorses of gearboxes with straight teeth that transfer power smoothly. You’ll find them in everything from conveyor belts to simple engines.

Helical Gears: Imagine a spiral staircase—helical gears work like that, offering quieter operation and handling heavier loads. They’re common in industrial machinery and automotive transmissions.

Bevel Gears: When shafts intersect at an angle, bevel gears step in. They’re vital for changing the direction of power transmission, often seen in vehicle differentials and marine propellers.

Worm Gears: Need precise control and high torque? Worm gears are your go-to. They’re perfect for conveyor systems and lifting equipment in construction.

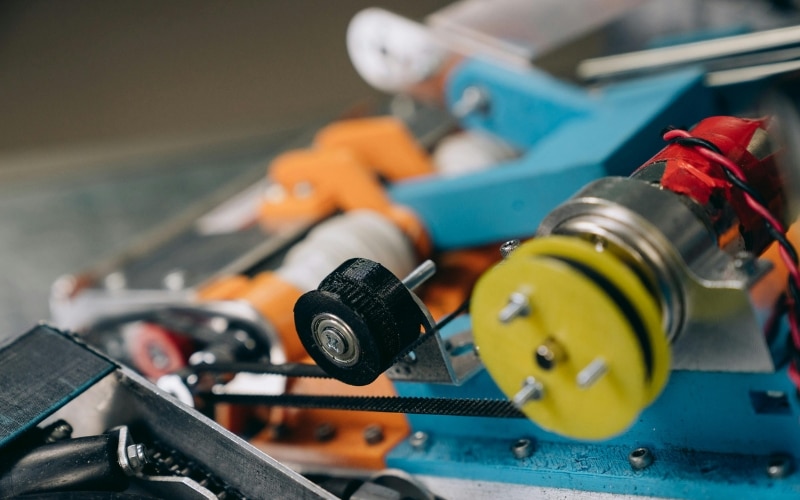

Planetary Gears: Compact and powerful, these gears resemble a mini solar system with a central gear (sun gear) surrounded by orbiting gears (planet gears). They’re ideal for reducing speed and increasing torque in heavy-duty machinery.

Hypoid Gears: Similar to spiral bevel gears but with offset axes, hypoid gears handle higher speeds and heavier loads. They’re essential in automotive rear axles and industrial equipment.

Understanding Gear Ratios: Gearboxes aren’t just about types; they’re about ratios, too. A gear ratio tells you how many times the smaller gear (pinion) rotates to turn the larger gear (gear). It’s crucial to match engine power to vehicle speed or adjust torque for heavy lifting.

Maintenance and Rebuilding: Regular maintenance keeps gearboxes running smoothly. Look for signs like unusual noises or vibrations, which might indicate worn-out gears needing replacement. When rebuilding, ensure parts are precision-machined and balanced to maintain efficiency.

Whether you manage industrial operations, maintain medical equipment, or oversee automotive fleets, knowing your gearbox types ensures you’re equipped to handle maintenance and upgrades effectively.

At Mayday, we specialize in gearbox solutions tailored to your industry needs. Stay tuned for more insights and tips on optimizing machinery performance. Stay informed, stay ahead, and let MayDay be your partner in optimizing machinery performance for a brighter industrial future.