Understanding Gearboxes: A Comprehensive Guide

Gearboxes are essential components in machinery, transmitting power efficiently while altering torque, speed, and direction. Whether you’re familiar with their essential functions or new to understanding their intricacies, this guide will provide you with a comprehensive overview of gearboxes and their significance across different industries.

What is a Gearbox?

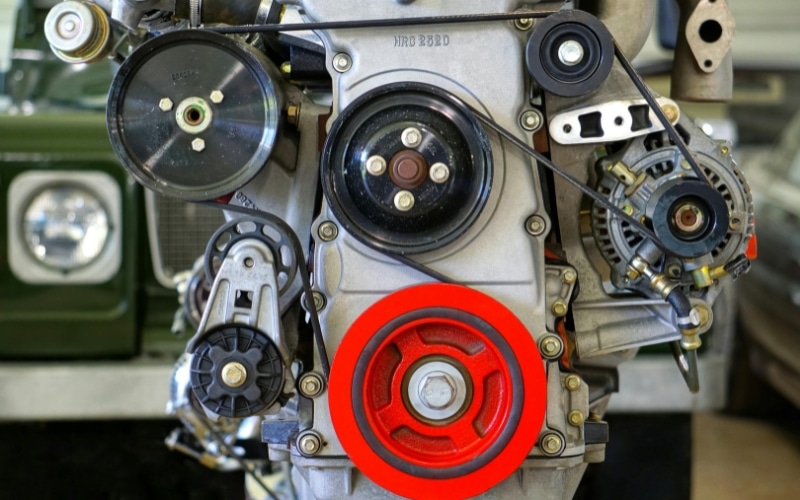

At its core, a gearbox is a mechanical device that uses sets of gears to transfer mechanical energy from a power source, like an engine or motor, to a driven load, such as wheels or machinery. By adjusting the configuration and sizes of these gears, gearboxes can increase or decrease rotational speed and torque output to match the application’s requirements.

Types of Gears in Gearboxes

Gearboxes can contain various types of gears depending on the specific application:

- Spur Gears: Straight-toothed gears are ideal for applications requiring high efficiency and moderate speeds.

- Helical Gears: Slanted tooth gears provide smoother and quieter operation than spur gears, which are commonly used in automotive and industrial applications.

- Bevel Gears: Conically shaped gears are used to transmit power between shafts that intersect at an angle, which is crucial in applications like vehicle differentials and machine tools.

- Worm Gears: Screw-like gears that offer high torque transmission are used in applications requiring precise speed reduction, such as conveyor systems and lifting mechanisms.

Applications of Gearboxes

Gearboxes are widespread across various industries. Here are a few applications across sectors.

Automotive: Found in vehicle transmissions to optimize engine power for different speeds and driving conditions.

Industrial Machinery: Used in manufacturing equipment to control rotational speed and torque, ensuring precise operation.

Marine Propulsion: Essential for transferring power from engines to propellers, enabling efficient movement of marine vessels.

Wind Turbines: Facilitate the conversion of wind energy into electrical power by adjusting rotational speed to match generator requirements.

Mining Equipment: Handle heavy loads and provide reliable power transmission in rugged mining environments.

Agricultural Machinery: Used in tractors and harvesters to regulate engine power for different farming tasks.

Maintenance and Considerations

Proper maintenance is crucial for gearbox longevity and performance. Make sure you’ve got a trusted partner for gearbox repair, rebuild, and maintenance.

Regular Inspections: Check for oil levels, gear wear and tear, and signs of overheating or abnormal noise.

Oil Changes: Maintain proper lubrication to reduce friction and wear between gears.

Environmental Factors: Consider operating conditions like temperature, humidity, and dust exposure when selecting and maintaining gearboxes.

Gearboxes play a crucial role in machinery across many industries, ensuring efficient power transmission and control. Whether you work in automotive engineering, manufacturing, or any field using mechanical systems, understanding gearbox types, applications, and maintenance is critical to enhancing operational efficiency and reliability.

For expert advice on selecting, maintaining, or troubleshooting gearboxes tailored to your needs, consult professionals specializing in gearbox technology, such as MayDay. Make your machinery perform better and last longer!