Exploring the Mechanics: Gears in Automotive Engineering

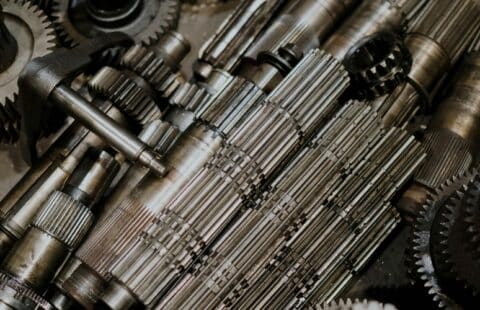

Gears are the unsung heroes of automotive engineering. They quietly but indispensably facilitate vehicle movement and functionality. From the seamless shifts of a manual transmission to the precise distribution of power in a differential, gears play a pivotal role in ensuring that automobiles operate efficiently and reliably.

This comprehensive guide from MayDay delves into the types, functions, materials, manufacturing processes, and maintenance of gears in the automotive industry, highlighting their critical importance and ongoing evolution in vehicle technology.

Types of Gears Used in Vehicles:

Gears are fundamental components in automotive engineering, serving diverse functions from transmitting power in transmissions to enabling precise engine timing and efficient steering.

- Spur Gears: Commonly used for parallel shafts in applications like manual transmissions.

- Helical Gears: Offer smoother operation and quieter performance than spur gears, often found in automotive transmissions.

- Bevel and Hypoid Gears: Used in rear axle differentials to transmit power at right angles while allowing space for the driveshaft.

- Worm Gears Provide high torque transmission with a compact design. They are used in steering mechanisms and some automatic transmissions.

How do gears work in vehicles?

Here’s the rundown.

- Transmission: Gears in the transmission allow drivers to shift between different speeds (gears) to optimize engine performance and fuel efficiency.

- Differential: Distributes engine power to the wheels while allowing them to rotate at different speeds, crucial for smooth cornering and traction.

- Steering System: Gears assist in converting steering wheel movement into directional changes for the vehicle.

- Engine Timing: Gears synchronize the timing of engine components like camshafts and crankshafts to ensure optimal combustion and engine performance.

What Materials are Used in Automotive Gears?

Each material is used due to its specific benefits. Here’s what you need to know.

Steel Alloys: High-strength steel alloys (e.g., 4140, 4340) are typical for gears due to their durability and ability to withstand high loads and temperatures.

Cast Iron: Used in applications where damping properties are important, such as gear housings and differential cases.

Aluminum Alloys: Lightweight aluminum alloys, such as those used in racing cars, are sometimes used for gears in applications where weight reduction is critical.

High-Performance Polymers: Plastics like nylon and PEEK are used for certain gears in automotive applications where noise reduction and weight savings are priorities.

What is the Gear Manufacturing Process?

Machining: Gears are typically cut from metal blanks using hobbing, milling, or shaping processes to achieve the required tooth profile.

Heat Treatment: Improves the hardness and strength of gears, enhancing wear resistance and durability.

Surface Treatment: Processes such as shot peening or nitriding can further improve gear surface hardness and resistance to fatigue.

Precision Grinding: Used to achieve precise gear tooth profiles and ensure smooth operation.

Maintenance and Repair of Automotive Gears:

Regular Inspection: Check gears for wear, damage, or misalignment to prevent more significant issues.

Lubrication: Proper lubrication reduces friction and wear between gear teeth and prolongs component life.

Gearbox Rebuilding: When gears show signs of wear or failure, gearbox rebuilding involves disassembly, inspection, replacement of worn parts, and reassembly to restore optimal performance.

Upgrades: Upgrading to advanced materials or improving gear design can enhance performance and efficiency in modern vehicles.

Future Trends in Automotive Gears:

- Electric and Hybrid Vehicles: Gears in electric and hybrid vehicles may evolve to handle different torque characteristics and optimize energy efficiency.

- Lightweight Materials: Continued developing lightweight materials for gears to improve fuel efficiency and reduce emissions.

- Advanced Manufacturing Techniques: Adoption of additive manufacturing (3D printing) and advanced simulation tools to optimize gear design and manufacturing processes.

As automotive technology advances, so will the role and capabilities of gears in vehicles. Whether optimizing fuel efficiency in hybrid cars or enhancing performance in high-performance sports vehicles, gears remain essential components that enable modern automobiles’ smooth and efficient operation. By understanding the types of gears used, their functions, and the importance of proper maintenance and materials, automotive engineers and enthusiasts alike can appreciate the intricate mechanics driving automotive innovation.